Creating Strategic Competitive Advantage Through Supply Chain Sustainability

Background: Why Supply Chain Sustainability Matters More Than Ever

Sustainability and digitalization are two important forces reshaping the global economy. While often treated as separate themes, their integration is now essential, particularly in the manufacturing sector. Sustainability is no longer a matter of corporate responsibility alone. It is becoming central to strategic decision-making, business models, and long-term competitiveness.

This shift is driven by six key forces shaping the business environment today:

- Politics, legislation, and regulation are making sustainability a requirement. The European Corporate Sustainability Reporting Directive (CSRD) is already in force, and further rules like the Corporate Sustainability Due Diligence Directive (CSDDD) and the Digital Product Passport (DPP) are increasing reporting and compliance demands. Despite the current noise around the Omnibus, regulation is getting stricter in the long term.

- Global sustainability commitments, such as the UN 2030 Agenda and voluntary initiatives like the Science Based Targets initiative (SBTi), are pushing companies to align with ambitious goals.

- Financial institutions now expect concrete sustainability performance. Banks and investors, including Nordea Bank and Norway’s $1.2 trillion sovereign wealth fund, are requiring better data on emissions and risks, linking sustainability to capital access.

- Changing consumer values are driving demand for more sustainable products. According to a 2022 KPMG study, over half of consumers now consider sustainability when making decisions. These values influence decisions inside companies as well, because it’s people who make the choices.

- Pressure from major customers like ABB and Danfoss is growing. Large manufacturers are requiring their suppliers to measure and reduce emissions, spreading sustainability expectations across the supply chain.

- Digital tools and platforms, such as Jakamo, now enable companies to improve transparency, automate manual data gathering, and focus procurement efforts on high-impact sustainability actions with suppliers.

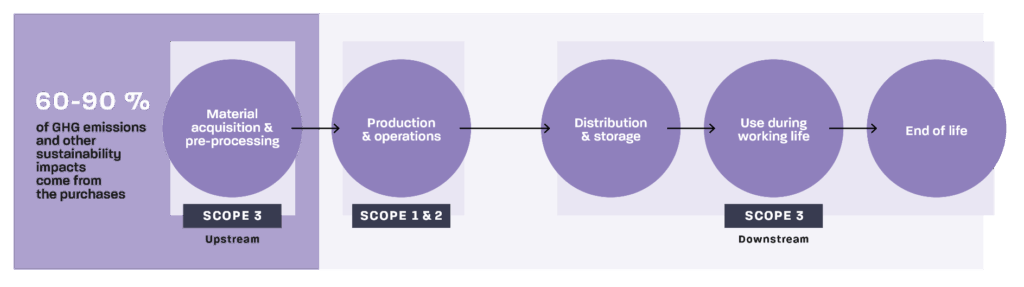

Together, these six drivers are creating a strong and growing need for companies to embed sustainability in their supply chains. For manufacturers, this is of critical importance. In this industry, supply chains represent the largest share of environmental and social impact. According to the CDP 2024 Global Supply Chain Report, Scope 3 emissions are on average 26 times higher than a company’s operational emissions. For manufacturers, up to 60–90 % of their environmental and social impact originates from their suppliers, as shown in Figure 1. This puts procurement, sourcing, and supplier collaboration at the center of any serious sustainability strategy.

Figure 1. GHG emissions footprint of a product in its value chain (modified image based on the GHG Protocol – McKinsey analysis)

However, progress is slow, and the question is why.

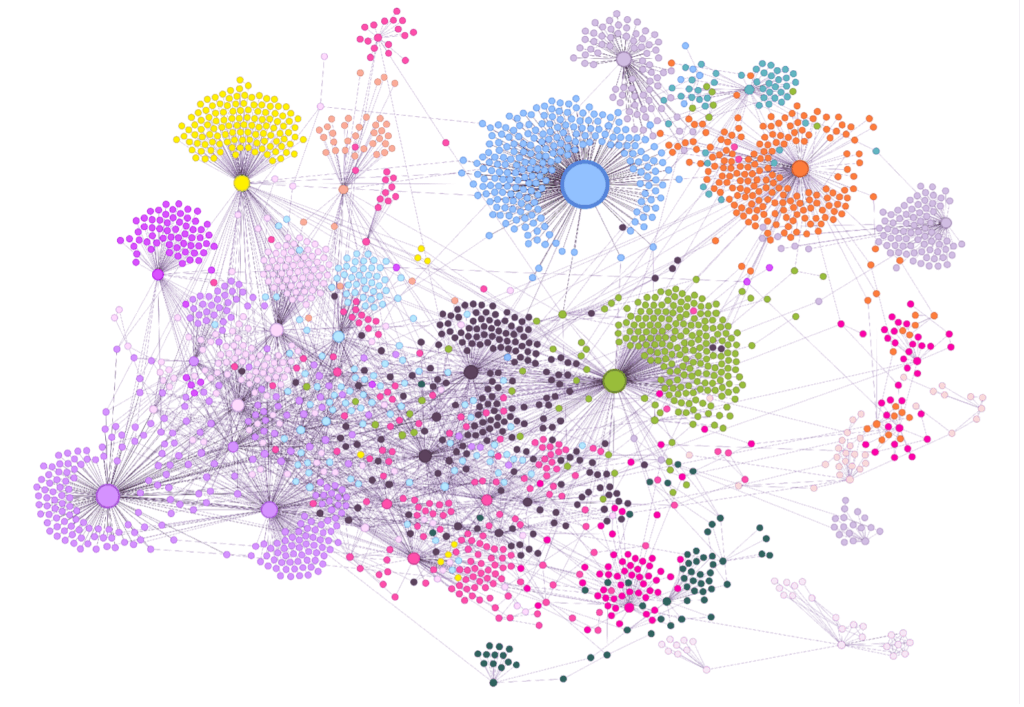

Firstly, Scope 3 impacts are significantly more complex to measure and manage compared to Scope 1 and 2, which fall under a company’s own control and internal decisions. This complexity is illustrated in Figure 2, where each circle represents a company and the lines show business relationships between them.

Figure 2. Ecosystem of Jakamo on 17 April 2024

Secondly, many companies still see sustainability as a cost, not an opportunity. Executives struggle to find a clear business case. Procurement teams are busy with manual tasks and lack the tools and training to act strategically. Although many talk about ESG goals, they often fail to turn ambition into real action. The result is small, scattered improvements with limited impact.

However, early pioneers are gaining strong advantages and setting the way forward.

Sustainability as a Competitive Advantage: What to Do in Practice

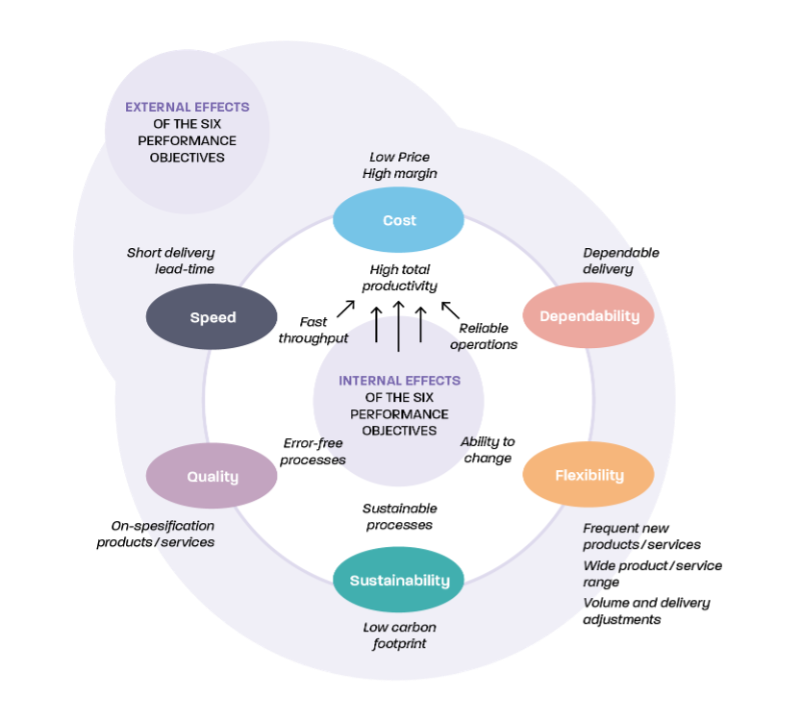

The traditional five key supply chain management (SCM) performance objectives—Cost, Quality, Speed, Dependability, and Flexibility—have long guided companies in building competitive supply chains that meet their market’s needs. Some businesses prioritize cost, while others focus on speed and flexibility to succeed.

However, one important performance objective has often been missing from these models and SCM literature: Sustainability.

With growing market pressure and tougher regulations, every company must invest in more sustainable business models and supply chains. Sustainability can and should be chosen as a core SCM goal, just like low cost or high quality. It is not just a cost or reporting requirement, it is a strategic choice that creates value and drives growth.

Figure 3. Performance objectives in SCM

From my recent discussions with top managers at many companies, I see three common approaches to supply chain sustainability:

- “This doesn’t concern us.”

These companies ignore sustainability and hope for the best. This is risky and may cause them to lose customers and market access. - “We meet the minimum requirements.”

These companies follow the rules and meet basic customer expectations. This keeps business running but doesn’t help the company stand out. - “We make sustainability a competitive advantage.”

These leading companies use sustainability to differentiate themselves—just like they do with cost-efficiency, quality, or flexibility. This opens new markets and improves both revenue and margins.

The first approach threatens the future of the business. Doors may close and opportunities disappear as expectations rise. The second approach helps companies stay in the market but does not build long-term strength.

The third approach is where real growth happens. It turns sustainability into a driver of strategic advantage, operational excellence, stronger customer partnerships, and long-term competitiveness. This is where the next competitive edge is built.

Three Key Parts of Supply Chain Sustainability

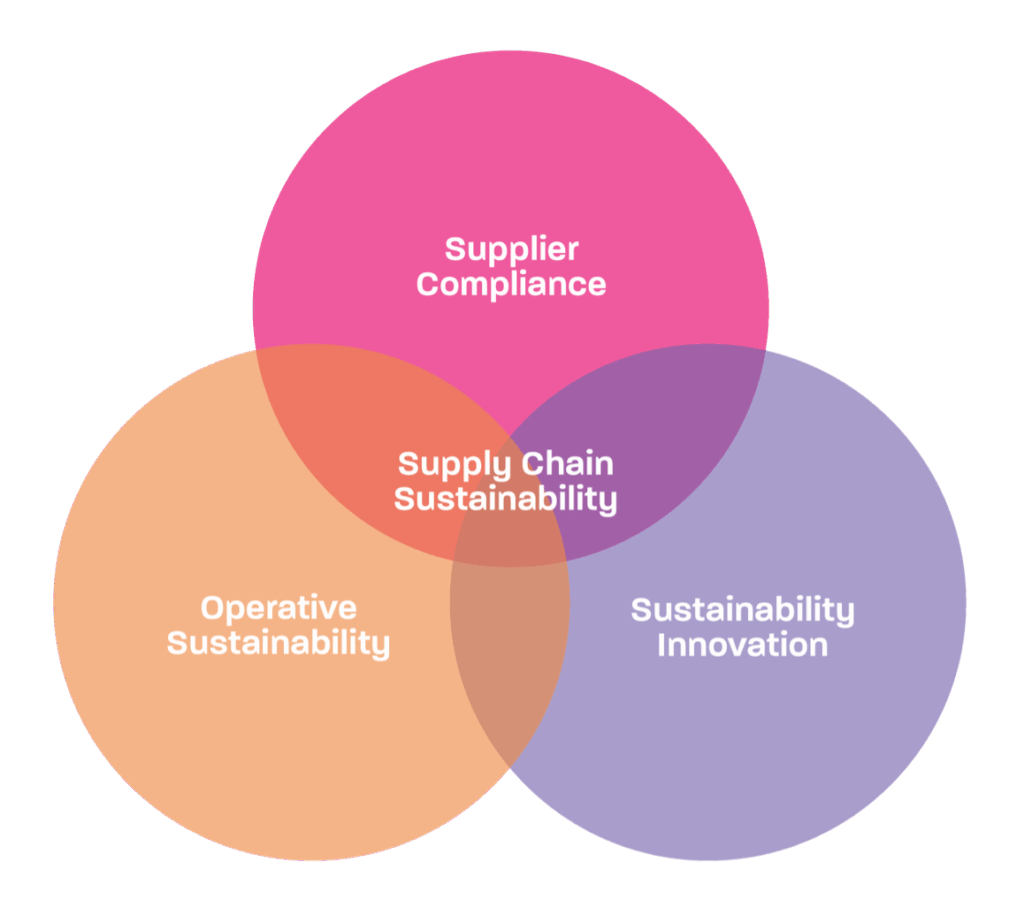

What does this look like in practice? I suggest focusing on three linked areas: Supplier compliance, operational sustainability, and sustainability innovation. These are not separate parts but support each other in a full transformation.

Figure 4. The holistic approach of Supply chain sustainability

1. Supplier compliance means understanding your suppliers’ ability to meet sustainability standards, not just through certificates and audits, but by truly knowing their capabilities, gaps, and willingness to improve. Digital platforms now help companies track this across hundreds or even thousands of suppliers. A central, transparent system makes it easier to identify risks, ensure visibility, and meet both market and regulatory requirements. It also helps procurement understand who their suppliers really are and where improvements are needed.

2. Operational sustainability means making sustainability part of daily work. This includes tracking greenhouse gas emissions and other impact data of purchased items. For example, integrating emissions tracking, energy efficiency, and material traceability directly into purchase orders and logistics. This not only improves reporting but also actual results: reducing waste, avoiding rework, and improving quality all help lower emissions.

3. Sustainability innovation is where breakthroughs happen. This means working closely with suppliers to co-create sustainable product designs, circular economy models, and process changes that reduce environmental and social impact. This could involve rethinking design, materials, or the whole product lifecycle. Innovation here can become a strong competitive advantage, delivering solutions competitors cannot match.

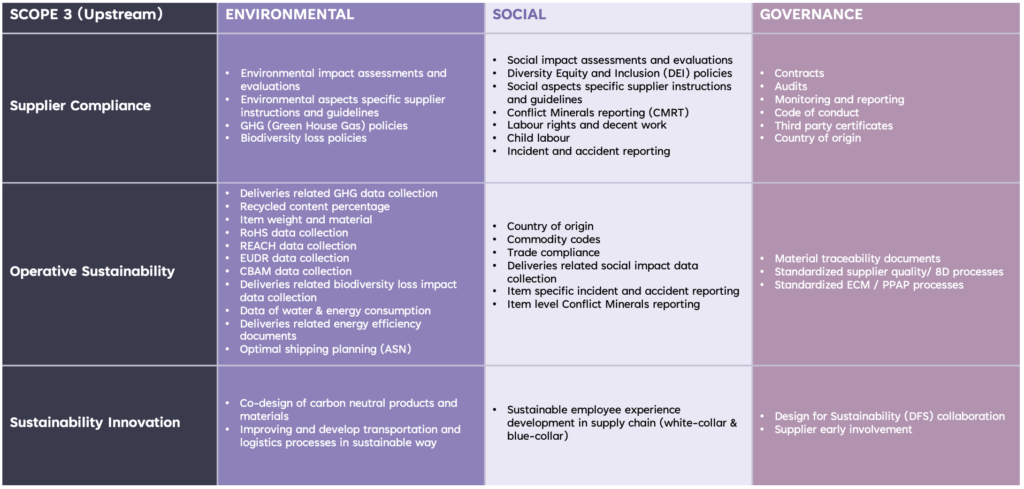

Digitalization is key across all three areas. Modern platforms make managing sustainability easier at scale. They automate routine tasks, freeing time for strategic work. They provide real-time data and traceability, helping track performance and share information. Most importantly, they improve supplier experience, building trust, transparency, and shared commitment. To provide more concrete examples, Table 1. below presents practical use cases demonstrating how digitalization can support the transformation of supply chain sustainability within the well-known ESG (Environmental, Social, Governance) framework.

Table1. Examples of digital use cases for supply chain sustainability transformation presented in ESG framework

Each company should identify its major sustainability data collection and improvement areas from these use cases and begin working on them. By excelling in these practical applications, companies can build a sustainable supply chain and a strong position in the market.

Conclusion: From Obligation to Opportunity

The case for supply chain sustainability goes beyond reporting, it is a source of competitive advantage. Companies that take it seriously gain clear benefits:

- Manage risk & stay prepared: Get real-time visibility into your supply chain to handle disruptions, changing customer needs, and new regulations.

- Win business: Customers choose suppliers who help them meet sustainability goals, supported by primary data.

- Improve margins: Verified sustainability makes you stand out, so you don’t have to compete just on price.

- Drive innovation: Co-innovate with suppliers to create new, sustainable, competitive offerings and stay ahead in the market.

By making sustainability a core supply chain performance objective, just like cost, quality, and speed, companies can build stronger supplier partnerships, drive growth, attract top talent, open new markets, reduce risks, and increase overall resilience. This strategic approach not only meets rising customer and regulatory expectations but also drives innovation and positions companies for long-term success in a rapidly evolving business environment.

Sustainability is not just the right thing to do. It is the smart thing to do. For manufacturing companies, supply chain sustainability is not a future trend. It is the new standard for success. Sustainability is not just a cost or a reporting obligation but a strategic choice that creates value and drives growth. Now is the time to act.

Want to get more information about Supply Chain Sustainability?

If this article resonated with you, sign up for our free newsletter – Supply Chain Sustainability Insights. Inside, you’ll get weekly, jargon-free insights designed to help you:

- Reduce risk

- Lead with confidence

- And turn ESG pressure into a competitive edge

All, without hiring consultants or wasting hours in webinars.

Join here: https://www.scsinsights.com/

References:

Bateman, Alexis & Leonardo Bonanni (2019). What Supply Chain Transparency Really Means, Harvard Business Review, August 20.

CDP Global Supply Chain Report 2024 – Strengthening the chain, Transform the Norm: Industry insights to accelerate sustainable supply chain transformation.

KPMG: Me, my life, my wallet consumer study, 2022.

McKinsey & Company: Building Sustainability into Operations, 2022

Rossi, Timo & Jarl Matti Anttila, 2024: SUPPLIER EXPERIENCE: The Fundamentals of Modern Supplier Collaboration. Supplier Experience Magazine, Jakamo Limited. ISBN 978-952-94-9057-8.

The World Bank: World Development Indicators, 2020.

The World Economic Forum: Reducing The Carbon Footprint of The Manufacturing Industry Through Data Sharing, 2022.

United Nations: Transforming our world: the 2030 Agenda for Sustainable Development, 2015.