From Customer & Employee Experience to Supplier Experience in Manufacturing Companies

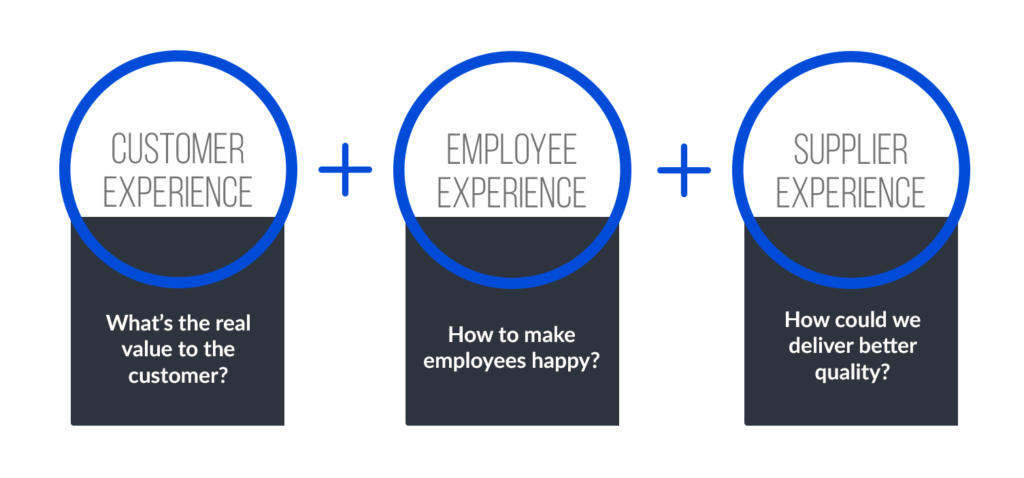

For a while, enterprises in different industries have been running their experience led projects. They are varying from customer-centric to employee or user experience led and trying to find ways to transform the old fashioned ways to deliver products and services to the customers in to a new operating model where the end-user, customer, or other party feel appriciated.

The theme connecting customer, employee, and other experiences

The connecting theme in all of the experience led development projects is how people experience something. How they feel, their thoughts on something, and would they recommend it to their peers. In the end the target with all of the activities is to find ways to be different, better, or be seen as the leader. The question behind the activities is that would someone who experienced something through them order again or recommend it to their peers?

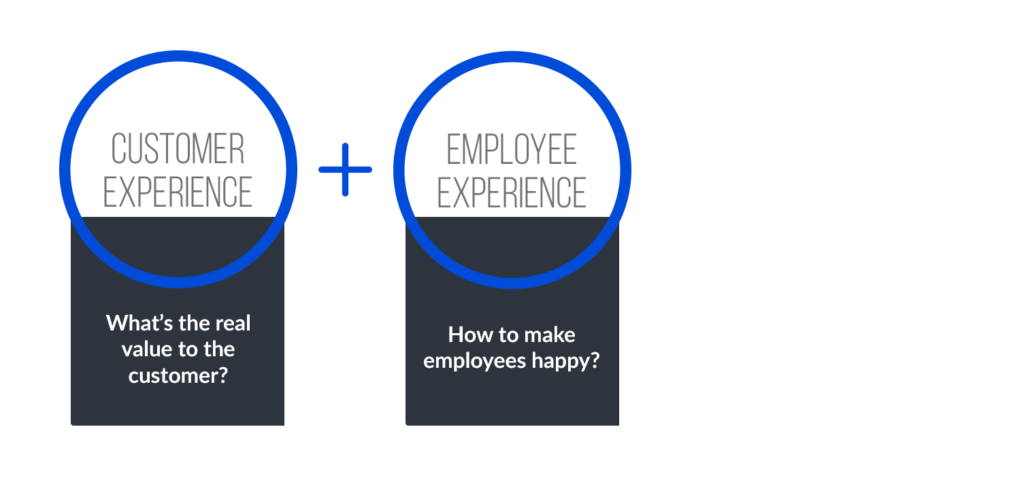

Customer experience is what initiated the experience wave in business

It all began with the need to map the customer journey and match it with the delivery process. This development project opened quite a few hidden gaps in delivering the perfect outcome to the customers.

Listening to the customers, employees, and other stakeholders in order to find places that could be further developed and new ways of interacting with customers. Finding a way to make customers feel appreciated and valued.

Data is the key to a successful customer experience project

One of the critical factors in Customer experience is the data and insights. This is the fuel that runs the customer experience projects and development. For all of the CX projects, the key is to have accurate and real-time data about the customers. This has been collected from different platforms and interactions.

Employee experience is bridging the CX gaps from an internal perspective

The employee experience (EX) in the manufacturing context can be described as a way to make the employee as the center of attention. They are listening, monitoring, and interacting with people from all parts of the organization. The target is to find new ways of working and finding ways to make employees happy. We all know that employees who like their job does always an extra mile even it’s not requested. Still, the main idea behind the customer experience is to think about how the process deliver the designed end-product into reality.

After most of the customer experience projects has been planned, many of the manufacturing companies realized that one of the critical success factors in customer experience is employees. How they work, communicate, operate, document, and deliver in day-to-day operations.

In the center of the development are people. In the wildest technology dreams, the whole process is fully automated and done by machines. But the reality today is still that most of the manufacturing processes require human and human interaction. This is why the employee experience is a critical part of the process.

Software is tightly connected to the employee experience. They are finding ways to ease the workload from employees with software, building better tools to collaborate with others, and bridging the gaps between other parts of the organization. The ultimate goal is to build one unified company with a shared target.

What’s next?

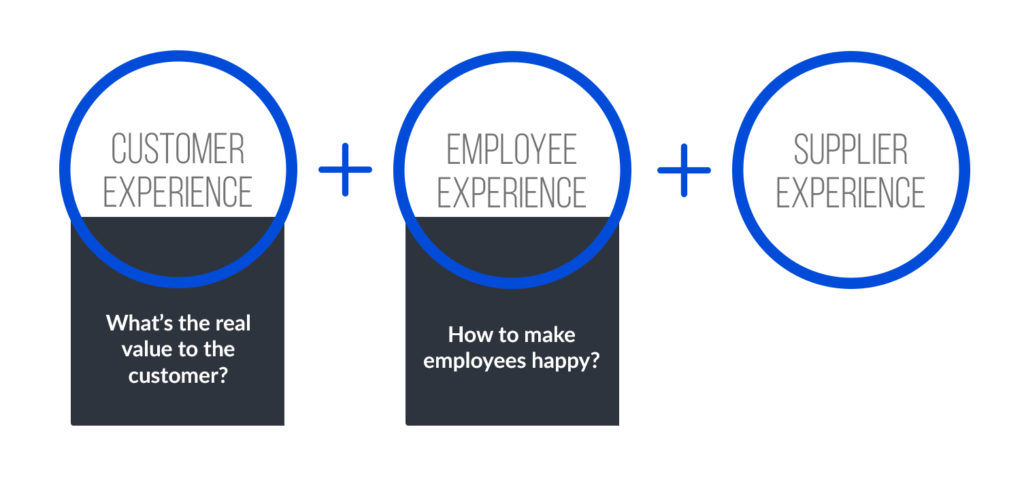

What’s the next trend in manufacturing ecosystem? Companies have spent time developing interaction with customers and found a new way to make employees happier. Rebuild some of the foundational platforms and being connected to all possible places.

If you try to deliver a perfect end-product to a customer in the manufacturing context, there is still one stakeholder who is a big part of the process – the supplier. These suppliers as a group build most of the parts required to deliver the end-product to the customer.

Building a perfect end product with suppliers

Today most of the suppliers have also been running their digital transformation projects. Most of them are ready to be digitally connected to the manufacturing companies’ inner circle. Suppliers are also looking at new markets, new ways of operating, and ways to automate. In some cases, the development process guidelines are being given from the manufacturing companies, and they need to obey based on it. As an exchange of these new processes, suppliers rarely get anything else than the normal business.

From living with what we got to a demand sensing

Suppliers used to live with the information that was available to them. This data was mainly related to their current ongoing projects with the customers. Today the advanced manufacturing companies are sharing the information they have in their systems to the suppliers. This new level of transparency opens up new opportunities for suppliers to prepare for upcoming needs and develop their offering to match the customers’ needs. This is called demand sensing (https://en.wikipedia.org/wiki/Demand_sensing).

The new transparency layer also gives an opportunity for a supplier to plan ahead. Invest in developing their capacity to deliver better quality, quantity, and/or at a lower cost. This is also immediately a visible element towards the end customer.

Collaboration over the borders

The collaboration between the customers and suppliers have been scattered around through different channels. These confusions have led to unexpected outcomes where human errors become even more obvious. Crucial information pieces lying in a personal email box could become a bigger issue than anyone could think of. Digital transformation projects rarely define how people should communicate. And as we know that people tend to find their own ways to operate.

What’s next?

Manufacturing companies are living a new normal where collaboration between different stakeholders is the key thing. Wheater its collaboration with customers, employees, or suppliers, the key thing is to focus on the experience.

I recommend reading our latest post to learn more about the definition of the supplier experience.