What is Supplier Experience and Why Should Every Executive Care about It?

Most of the executives are already familiar with the concepts of Customer Experience, Employee Experience and User Experience. There is no doubt that they all are significantly important for companies’ success. But how many have ever heard or thought about Supplier Experience? And why should every executive care about the Supplier Experience?

The End-customer will see the outcome of poor supplier experience

Today in a manufacturing context, the products are produced in global and complex supply chains. Companies are very dependent on the performance of their procurement and suppliers in many ways, for instance:

- Costs – purchases from suppliers can cover up to 80 % of the company’s cost structure

- Quality – suppliers play a key role in fulfilling the quality of the deliveries to the end-customer

- Shortages and delays in suppliers’ deliveries can cause serious problems

- Sustainability – a significant share of companies’ environmental and social impact is coming from the suppliers and sustainability deviations in the supply chain can cause serious problems for companies’ competitiveness

- Technology – suppliers are developing and delivering crucial technologies that are difficult to substitute

The Covid-19 pandemic has shown us how vulnerable companies can be when suppliers cannot deliver the essential components on-time, or at all. Therefore, it is important to think about why your suppliers would serve you over other companies generally, and especially, in a state of emergency. Customer companies, especially purchasers, need to solve the challenge of how they could improve their relationship with suppliers and become their preferred customer. This should not only be on the agenda of procurement but rather prioritized by the whole company management – because the end-customer will see the outcome of poor supplier experience.

Even so, the importance of suppliers for a company’s overall performance is often overlooked, or if not totally forgotten. Many supply-chain-related problems could be avoided by taking a holistic view in managing and developing supplier relations bi-directionally both at the operational and strategic levels. According to our research in the manufacturing industry, the typical topics causing problems in customer-supplier-relations are:

- Lack of strategic cooperation i.e. common targets and open governance

- Manual time-consuming processes and non-existent operational transparency

- Poor cross-organizational communication and interaction

- Silo-type of thinking in value chains

- Lack of understanding and concreteness regarding supply chain sustainability initiatives

The concept of supplier experience

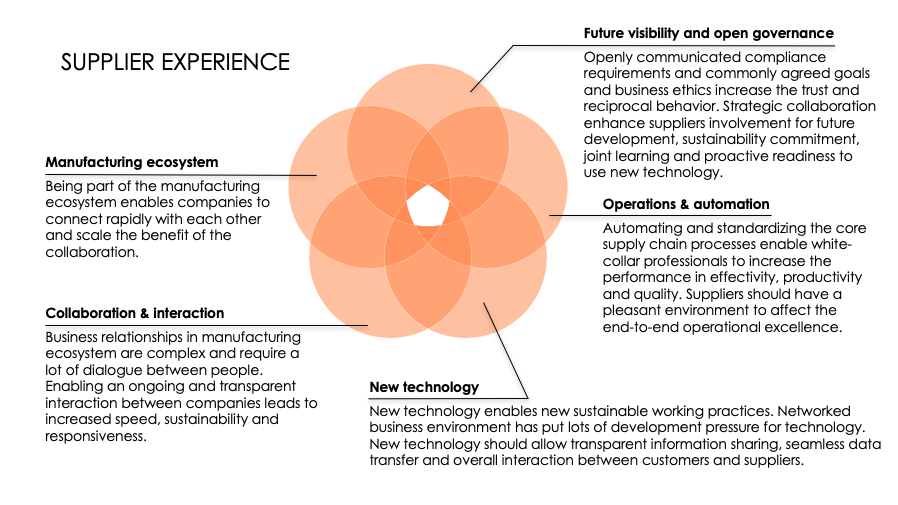

For solving these problems and improving the company’s overall performance it is essential to recognize the value of the suppliers. We want to take this in the loop by introducing the concept of Supplier Experience. It is holistic by its nature and approaches customer-supplier relations from the viewpoints presented in the picture below:

Figure 1. The concept of supplier experience.

Future visibility and open governance. Commonly agreed targets and openly communicated compliance governance are vital parts of successful Supplier Experience. It increases trust between the business parties and ensures a fruitful ground for healthy business collaboration and value creation for the end-customer. Supply Chain Governance and Security was one of the eight topics Gartner reported in their Top Supply Chain Technology Trends in 2020.

Most importantly, future visibility means the parties of a relationship share the same accurate information concerning the expectations. The future visibility in the business relation strengthens the psychological linkage with the supplier. It affects on supplier’s involvement in the future development and how the supplier will behave towards the customer, especially, in challenging circumstances. When there’s trust in the business relationship, the supplier is more willing to adopt proactively new operation models, sustainability, and digital solutions that will benefit the end-customer’s needs as well.

Operational transparency and automation. Today, a lot of time is wasted in business relations, for instance, in searching information, creating reports, waiting for someone to send you some critical information, typing the same information multiple times manually to different systems of different companies. The common challenge is how to share and manage information and to collaborate between companies. There is a huge potential to improve the white-collar productivity of a value chain by reducing manual work and ensuring that the needed information is easily available whenever and wherever.

The automation of information processes, standardizing the manual supply chain processes, allowing fast information availability and real-time reporting should be on the agenda of all manufacturing companies. It will lead to improved delivery performance including increased effectiveness, productivity, and quality from the end-customer’s perspective.

Automation of a supply chain activity greatly streamlines routine supply chain processes and decreases costs generated. When people do not need to spend time in manual routine work they can do something that really creates customer value. It releases significantly personnel’s time to work with more value-added activities, such as development, relationship management, learning, and optimization. Furthermore, this type of work is usually much more pleasant for employees than manual routine work. Certainly, transparent information sharing and automated processes between customers and suppliers strengthen the sustainability and competitive advantage in the competition of value chains.

New technology. Technological development has faced new requirements during the latest years. New technology should enable new working practices for people. Especially the software and cloud services have moved towards a design based on human/technology intertwinement approach. Customers should provide their suppliers a delightful environment to serve them from a technological perspective as well.

In general, new technology should allow business partners transparent information sharing in real-time, seamless data transfer by automation, and context-based overall interaction between customer’s and supplier’s personnel. A negative experience using rigid and complex digital tools does not serve the mutual goal achievement in a business relationship.

New technology is a key enabler for manufacturing companies in supply chain sustainability. Digital platforms will support supply chain sustainability at many levels by providing visibility, concrete use cases, and manageability for suppliers’ compliance, development & innovation initiatives, and operative supply chain processes.

Excellent collaboration and interaction. In a manufacturing context, the customer-supplier relationships are not faceless organization-level entities. The business relationships are complex and require a lot of dialogue between the professionals both on the customer and supplier side. Therefore, interaction is the core of daily work. Purchasers are responsible for establishing and maintaining supplier relationships, while they also need to respond to the needs of multiple parties within their own organization.

Ongoing context-based interaction has become a necessity for successful delivery management. It includes such practices as common value creation, co-development, supplier involvement in R&D, joint learning, and especially joint problem-solving and decision making. Excellent collaboration and interaction between companies enhance speed, flexibility, responsiveness, sustainability, and productivity of the relationship and in the whole value chain towards the end customer.

Manufacturing ecosystem. Being part of a growing manufacturing ecosystem enables companies to connect with each other smoothly, rapidly and securely, on a global scale. The possibility to connect with companies existing already in the manufacturing ecosystem instead of several traditional hierarchic silo-types of value chains improves the connectivity and standardizes processes, IT systems, and ways of working in supplier-customer-relations.

Besides, it reduces the complexity and improves the overall sustainability of the value chain and will certainly benefit the end-customer as well. How to improve connectivity capability, not only on the personal level but also on the organizational level, is a key question for manufacturing companies in the near future.

The effects of a good supplier experience

New technology – modern software and platforms – enable increased transparency, improved communication, and standardized and structured ways to manage the supply chains holistically and in a sustainable way.

It is possible to take a huge leap at the company level to fulfill the end-customer’s demands by focusing on the Supplier Experience. This should not only be in the procurement’s interest as it requires strong commitment and understanding of the top management in the company.

By taking a holistic view to the management of supplier experience both at the operative and strategic level, the company can become their suppliers’ preferred customer and achieve remarkable benefits regarding delivery performance, quality, responsiveness, sustainability, costs, and technological development.

This is the second edition of this article which was published first time in Supplier Experience Online Magazine on 1 OCT 2020.